Illinois began accepting applications to grow industrial hemp at the end of April. But the first legal crop in more than eighty years is accompanied by a lot of uncertainty.

By Avery Gregurich

It’s an afternoon in late May, and Trent Lawrence, owner and operator of Lawrence Family Farms, near Delavan, Illinois, is cutting the seal of a manila envelope with a pocket knife. The envelope is from somewhere in North Carolina, and inside is a Ziploc bag half-full of industrial hemp seed. These are among the first (legal) seeds of their kind to arrive in Illinois, and for Lawrence and hundreds of other farmers across the state, they represent a potential for sustainability in an industry struggling to hang on.

So far, Lawrence has gotten seed from North Carolina, Oregon, and Colorado, all purchased online and delivered via mail. He describes the whole endeavor of buying hemp seeds online, which he says can quickly add up to five-figure wire transfers, as “nerve-wracking.” “There’s a lot of charlatans out there. There’s a lot of snake oil salesmen,” he says. “There’s a lot of people who will gladly rip you off.”

In the indoor grow room in the attic above his office space, Lawrence points out the first “true leaves” of his hemp plants, planted just ten days ago. “What fascinates me about this is how big of a felony this would have been six months ago,” he says. “We used to joke about it: Can you imagine what we could grow in here?” Now, there are eight thousand hemp plants in here. He jokes they are happiest when he plays them Jimi Hendrix and Jefferson Airplane. Counting the package of seed that arrived today, the number of plants will grow enough to fill between three and five acres of organic soil on his farm.

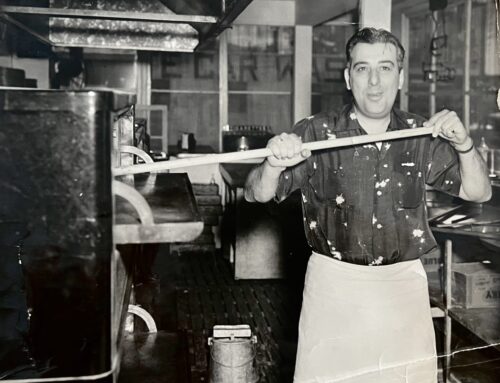

Trent Lawrence spent most of his life as a computer programmer. Now, in his second year farming, he has converted the attic above his barn into a fifteen-hundred-square-foot indoor growing facility. Photo by Avery Gregurich.

This is what the fledgling hemp industry looks like in Illinois after the 2018 Federal Farm Bill legalized the cultivation and processing of hemp nationwide last December. States across the country rushed to implement rules and regulations in time for farmers to plant a crop this spring. After a months-long process, the Illinois Department of Agriculture began accepting applications on April 30, which led to this unexpected rush for farmers, both large and small, to acquire seed and plant it in a short window.

As of June 13, there were four hundred and ninety two growers’ licenses approved by the Illinois Department of Agriculture, and more than one hundred processor applications. That equates to more than twelve thousand acres of farmland dedicated to hemp production in the state. And it’s not just small farmers like Lawrence who are interested in the crop. Conventional farmers—whose industry has been affected by recent tariffs on global trade and the slowest planting start in recent history—are looking to alternatives, like hemp, to make their farms viable this year.

Last month, I visited a couple of small farmers who are growing hemp in Illinois. Hemp is sometimes touted as a miracle plant, and has recently garnered headlines like, “Will Hemp be Illinois’ Next Billion-Dollar Bumper Crop?” Outside investors are flocking to the state, which will now host the world’s largest indoor hemp production facility. But what does all this potential actually mean for struggling farmers in Illinois?

Industrial hemp is a member of the plant species cannabis. While nearly identical in appearance to marijuana, industrial hemp has markedly lower levels of THC—the psychoactive compound that makes you “high.” To be categorized as industrial hemp, a plant must contain less than 0.3 percent THC. Hemp has been grown for centuries and used for everything from paper and textiles to food and fuel. Farmers in Illinois will be growing hemp to be used for three distinct products: hemp fiber, hemp seed, and CBD oil.

Growing legal hemp commercially for the first time in eight decades is a complicated endeavor. “There’s a lot of uncertainty. It’s so new. I think it is going to be a learning year for many farmers,” says Liz Rupel, who works as a policy organizer for the Illinois Stewardship Alliance, a local food organization that was instrumental in passing Illinois’ 2018 Industrial Hemp Act.

Eric Pollitt is the founder of Global Hemp Inc., a hemp retailer that has been operating in Peoria, IL, since 2003. He has been urging legislators to get industrial hemp legalized and regulated in the state since 2014. Last year, he was one of only a few farmers allowed to grow hemp in the state as part of a pilot program. Pollitt believes that most farmers in Illinois and beyond are looking to cash in on the hot market for CBD oil, which Transparency Market Research has estimated will grow into a $2.5 billion industry by 2026. “For Illinois farmers, CBD oil is where this big huge market is at, short term,” Pollitt says. “I think that bubble is likely to burst at some point.”

Industrial hemp is still under strict regulation by the Federal Drug Administration. On May 30, the agency held its first public hearing regarding the regulation of products containing substances derived from cannabis. It was, at best, very confusing. Currently, CBD is banned for use in all food products, leaving many in the industry fearful of the possibility of the FDA imposing more restrictions on CBD in the coming months, just as the first legal crop would head to market.

There’s also the practicality of harvesting and processing this highly-regulated crop. As a hemp plant progresses, its percentage of THC increases exponentially. Throughout the plant’s growing season, farmers are subject to random tests by the Illinois Department of Agriculture to ensure that their crops are staying below that benchmark of 0.3 percent of THC. Jeff Cox, the Chief of the Illinois Department of Agriculture’s Bureau of Medicinal Plants told me that the state will not be testing every farm’s levels, but will be selecting a random subset of all farmers with approved hemp applications. “The 2018 Farm Bill says that it has to be a random inspection, so it’s not that everyone has to be inspected,” he said. “Once we have a final number of people that are in the ground, we will come up with a number that we can handle, whether that’s five percent or ten percent [of the applications].”

One of the many packages of legal hemp seeds that have arrived at Lawrence Family Farms near Delavan, Illinois. Trent Lawrence places each of them by hand, with tweezers. Photo by Avery Gregurich.

If at any point the levels of THC in the hemp rise above 0.3 percent, the Department of Agriculture’s rules state that “the opportunity for a retest is available in some situations.” If the hemp tests above 0.7 percent THC, however, “it must be destroyed.” “The biggest concern when it comes to testing is that this stuff hasn’t been grown in Illinois in decades, and back then it wasn’t tested for THC because it was all going to fiber use,” Cox says. “The nice thing is that if it is a negligent violation, we will work with the farmer to make sure it doesn’t happen in the future. We will have to destroy the product potentially, but it’s not like we are going to go out and handcuff these guys.”

Meanwhile, farmers will be responsible for keeping their crops safe from potential theft or damage—a task made more complicated by hemp’s similarity to weed. “You can’t tell by look, smell, touch, or taste that these are any different than marijuana,” Lawrence said. “It always worries me that somebody is going to show up and snag twenty or fifty pounds of it and then sell it on the street as marijuana, because you can’t tell the difference.”

Lawrence says there are already surveillance cameras in operation at his farm, and that there will be armed security there twenty-four hours a day during harvest time. He says that many farmers are caught in a kind of catch-22. “On one hand we have to market this stuff, which tells the world, ‘Hey, we’re growing it.’ On the other hand, that tells everybody that we’ve got this stuff,” he said. “What’s really mind-numbing about this is that I have a few hundred thousand dollars of potential harvest sitting in one room.”

An hour south of Lawrence Family Farms, I visited Oak Tree Organics, situated on eighteen acres of converted conventional farm land in rural Ashland, Illinois, about thirty miles west of Springfield. Here, Chad Wallace grows vegetables, herbs and fruit, and raises pork and lamb. Today, the floor of his greenhouse is covered in one-week-old hemp plants planted in repurposed tomato trays. “Most of these have been planted from ten at night until three in the morning,” he says, studying the trays. “When I got my license, this was plumb full of vegetables still. I had nothing set up. I’m waiting on more containers, more trays.”

The corn and soy fields surrounding his farm hold standing water, and his vegetable fields look much the same. Plastic six-packs of broccoli, kale, and other vegetables flank the entrance to the greenhouse, unable to be planted out into the flooded fields and displaced from the greenhouse by what Wallace describes as simply “the unknown.” “The vegetable end is definitely being neglected. Had the hemp thing not been here, it’d look a lot different in here,” he says. “It’s all experiment. I’ll be way better set up next year. This isn’t the perfect environment to do all of this, so I’m basically winging it.”

Standing in his greenhouse at Oak Tree Organics, Chad Wallace says he worries about his hemp plants “all the time.” He says that he’s planted most of them between ten p.m. and three a.m. Photo by Avery Gregurich.

Wallace has been operating Oak Tree Organics for the last fifteen years, working the same land where he was raised farming with both his grandfather and father. Over the years, most of his business has been at farmer’s markets in Springfield, which he says is fittingly in the shadow of the capitol building. Now, he says, the competition among vegetable producers there has grown right along with the yearly fee he has to pay to set up shop. He says he needs other revenues to keep his farm viable for the future, and that’s why he’s been so vocal on hemp.

He’s worked to make what is growing in his greenhouse today a reality since 2016, speaking to countless legislators and two governors, giving them what he calls his “bring the family back to the farm” speech. Now, at fifty years old, he is working more than he ever has, in the hope that hemp will make it possible for his son, who has had to look for work elsewhere, to come back to the farm and work alongside him.

Wallace plans to plant around three acres of hemp this year. When I ask him how he is going to harvest and dry his crop, he says he still isn’t sure. There are several options: some farmers are going to hang it up in barns and greenhouses and hope that the temperatures in August stay down; others are going to get more inventive and try to dry them in a hops dryer.

“That’s the craziest thing about this: You can only go so far on what you have to know for right now. We’ve been spending most of our time on learning how to grow this stuff,” he says. “Now that we’ve got this stuff in, now we’re starting to think about the next phase. People are like, ‘What are we going to dry it in?’ And, ‘Where am I going to get rid of it?’”

He says he was recently talking with a young man who has worked at hemp farms in Colorado and has been helping Wallace get set up this year. “He started talking about all of these terpenes that hemp has, and I was like, ‘Man, I am so far behind on this.’ Then, that last twenty minutes before your eyes finally shut, you’re laying in bed and you’re trying to learn about this product that your going to have to offer,” Wallace says. “That’s what kind of game it’s been, and in between, go ahead and try and do what you’ve been making money doing so you can feed this new industry.

Wallace says that his wife can tell that hemp now has the priority here, evidenced perhaps best by the plastic six-pack of hemp plants growing in Wallace’s living room window. He had what he thought were not viable seeds, but planted them anyway and brought them inside. Three came up and three didn’t, a coin flip that Wallace is constantly mulling over. “You think about [the hemp plants] all the time,” he said. “You’re wondering, ‘Am I doing it right?’ ‘Should they wiggle that much?’ ‘Should I fill them up with more dirt?’ ‘Should I put some extra shade on them during the day?’ You are learning what you need to know for tomorrow today.”

Back at Lawrence Family Farms, Trent Lawrence is optimistic about the crop’s potential. He says that’s why he got into farming in the first place, now, at forty-two years old, after a career designing and building supercomputers. “I wanted something that I could do work and have something to show for it. With technology, everything that I’ve ever built, most of the systems and software I’ve written as a software engineer, the networks that I’ve built as a network engineer, and all the equipment that I’ve put in and configured has all become obsolete,” he said. “Some people would call this a mid-life crisis. I call it a change of pace.”

The indoor grow room at Lawrence Family Farms near Delavan, Illinois. Trent Lawrence says that after the rules for industrial hemp were approved, he outfitted this attic space in less than a week. Photo by Avery Gregurich.

In just his second year in the agriculture business, Lawrence is relying on whatever vegetable growing experience he has gained to grow this new crop. “I actually learned how to grow hot peppers by reading marijuana boards because there really wasn’t anything on hot peppers. They’re very similar,” he told me. He’s one of the most active members of an online community of Illinois farmers aggregated together by the Illinois Stewardship Alliance, sharing daily updates and answering other farmers’ questions.

“I’m trying to help other farmers, because the farmers who do commodity crops, they’re not going to be accustomed to a manual harvest crop,” he says. “They’re not going to be accustomed to doing weeds by hand. Nobody was really expecting hemp to go through this year. Overnight, my workload doubled, so I’ve been working sixteen to eighteen hour days ever since we got our application.”

At Oak Tree Organics, in the same soil where his family has farmed for three generations, Chad Wallace finally sees in hemp a future that includes a fourth. “I’d love for my son to be able to come back and work on this farm like I did with my father and grandfather,” he told me. “So that’s in the initial intent: to try to make something for the next generation.”

Standing at the end of his driveway, Wallace tells me a story about when the county was remaking the road that runs by his farm, decades ago. Wallace’s dad was running the farm at the time, and the county paid him for the land and the fence that they removed to remake the road. Wallace says that he took that check and bought his wife a new car. “I love this farm, and it’s not as big as it used to be. But still, it’s like my scrapbook. You know?” he says. “Everywhere I go, there’s something I did with my grandfather, my father, you know, it’s just your life.”

After a Midwestern winter that stretched well into spring, and record-setting rainfall both here in Illinois and across the region, Trent Lawrence says that hemp is the only hope left for his family farm to make a profit this year. Walking through his farm on the day I visited in late May, he still had several inches of standing water where his vegetables were supposed to be.

“It’s been a rough year, gut-wrenching at times,” he said. “Without hemp, I don’t know how we would be able to survive for another year, after losing all of our spring and mid-summer crops. We have to go in the direction that we are going to make a profit. Whether that means growing sweet corn or cannabis, it doesn’t matter to me.” ■

Avery Gregurich is a writer living and working in Des Moines, Iowa. He was raised next to the Mississippi River and has never strayed too far from it.

Belt Magazine is a 501(c)(3) nonprofit organization. To support more independent writing and journalism made by and for the Rust Belt and greater Midwest, make a donation to Belt Magazine, or become a member starting at just $5 a month.