What’s left of domestic glass manufacturing in the U.S. remains concentrated in the Rust Belt–eight of the industry’s top ten employers are in Pennsylvania, New York, and the Midwest. But studio glassblowing is adding relevance to a material long forgotten by many communities shaped by it. Today, the Rust Belt is home to three of the United States’ top five hubs for glass studios.

By Dora Segall

Rastin Observation Tower shoots up into space like an alien monolith amidst a neighborhood of rickety houses in Mount Vernon, Ohio. A metal, spiral staircase twists around the out-of-use smokestack; from the top, you can peer down at the rest of Ariel Foundation Park. It’s a lush, green expanse dotted with factory ruins that levels rise up to form grassy, ziggurat-like terraces where children play on warm days. A “river” made from glass left behind during the site’s manufacturing days cuts through the earth on one side of the park, frozen in time. The park is an homage to Pittsburgh Plate Glass, whose company once dominated the small city. Like communities all over the Rust Belt, glass has a long, rich history in Mount Vernon.

Glass can be easy to overlook, but its influences are everywhere. Glass manufacturing came to western Pennsylvania, eastern Ohio and the northern panhandle of West Virginia in the late 1800s, when companies were taking advantage of the region’s wealth of fuel sources. It shaped towns and cities, employing thousands and spurring economic development. In the century and a half since, glass has served as both an industrial material and an artistic medium. Today, Rust Belt artists are reimagining glass’s potential uses.

Clear foundations

Glassmaking was technically colonial America’s first industry, with a rudimentary glass shop opening in Jamestown in 1608. The workshop didn’t last more than two years, and a second attempt in 1622 was also a failure. Glass production finally became profitable in the early 1800s, when several companies emerged in New England. From 1820-1860, the glass industry grew fivefold. It even became one of the United States’ biggest employers until the beginning the 20th century, according to Barbara Floyd, retired director of special collections at the University of Toledo and author of the book The Glass City: Toledo and The Industry That Built It. Due to the extensive menial labor it required, however, many of the workers were children. A typical workshop in the late 1800s included a skilled glassblower (who usually made two to three times more than other industrial workers at the time) and four young employees referred to as “boys.” In glass bottle production, the “mold boy” fitted a cast around the molten glass before the skilled worker blew into a blowpipe to shape the viscous material. Another boy then cracked the finished piece off the blowpipe before handing it to a third boy to put in the annealing lehr, a chamber for glass to cool.

Glass manufacturing moved westward along with other industries in the middle of the nineteenth century. First, companies established factories in areas closer to coal fields, like western Pennsylvania and West Virginia, in order to cut down on the cost of transporting fuel. Then came the discovery of natural gas. Pittsburgh Plate Glass became the world’s first plate glass company to power furnaces using local reservoirs. After that, the industry as a whole moved even further westward, where natural gas was plentiful.

Glass manufacturing in New England collapsed for two reasons–the cost of fuel and the rising strength of the labor movement. Glass was one of the first American industries to unionize, with a group soon called Glass Blowers’ League forming in the 1840s. Then came the American Flint Glass Workers’ Union, which formed when several members broke off from the newly formed Knights of Labor in 1878.

Demands for better wages and work conditions pressured glass companies to cut costs elsewhere, accelerating the fallout of east coast factories to those closer to cheap fuel and workers willing to labor without the same protections earned by their colleagues in the east. By 1902, western Pennsylvania, eastern Ohio, and the northern panhandle of West Virginia were home to 150 glass factories. By 1920, following the discovery of natural gas and oil there, the region was home to 80% of glass manufacturing in the United States.

Building glass houses

Glass manufacturing influenced entire cities and built towns. Pittsburgh was first to claim the title of America’s “glass city,” opening its first two factories in 1797. Next came Toledo, which emerged as New England Glass Company’s new headquarters in 1888; the manufacturer rebranded itself as Libbey Glass soon after. Toledo became a national center for the glass industry, eventually housing four of its major companies. Along with freight and water transportation, glass allowed Toledo to prosper, its population swelling with domestic and foreign migrants. In 1850, the census noted 3,829 residents; by 1930, it counted 300,000.

Not just important to large cities, glass was also often the primary economic driver in smaller towns as well. Corning, New York became a glass hub in 1868, when the company now known as Corning Inc. relocated there from Brooklyn. In the late nineteenth and early twentieth century, the town became known for its fine-cut glass, earning it a reputation as the “Crystal City.” To this day, local employment largely centers on Corning Inc., whose headquarters and research facility remain there.

The Pittsburgh Plate Glass plant in Mount Vernon, Ohio opened in 1907, a “mill village” growing around it. The city’s population shot up from about 6.5 thousand to around 9,000 between 1900 and 1910.

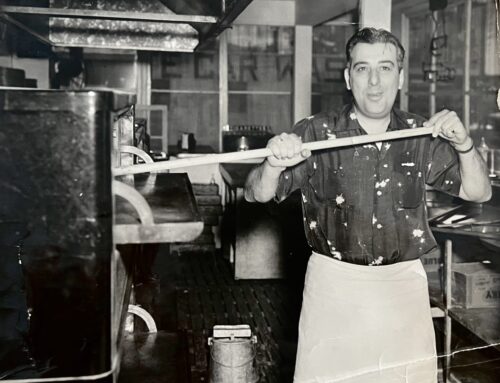

Streator, Illinois became a glass town in 1881, when a plant opened under the name Streator Bottle & Glass Co. Now part of Owens-Illinois, the bottle-making factory often employed multiple members and generations of local families. Wages were relatively higher in glass manufacturing when compared to other industries, according to Donald “Butch” Carter, a former glassworker and current representative for the Glass, Molders, Pottery, Plastics and Allied Workers Council of the United Steelworkers Union.

“Everybody took turns, but you took that blowpipe,” he says, “and when it was your turn, you handed it to your brother, or your nephew, or your cousin. You handed it to a family member.”

Booms and busts

Early 20th-century developments in automation, like the Owen Bottle Machine, dealt a blow to child labor and wages, but they proved lucrative to companies–industry employment grew to 139,100 by 1960.

The first big loss for glass manufacturing was Prohibition. Throughout the 1920s, demand for glass bottles plummeted. The industry suffered even more during the Great Depression. Manufacturing bounced back during World War II, with new technology like bullet-resistance windshields and fiberglass fabric for the wings of airplanes.

U.S. glass manufacturing experienced a longer-term blow in the latter half of the twentieth century. The 1973 energy crisis created fuel shortages across industries. Glass also struggled as car manufacturing slowed, lowering the demand for windshields. Owens-Corning, a top U.S. glass manufacturer, encountered another setback starting in 1980. The company had produced asbestos earlier in the century, and once the health hazards became clear, it was inundated with lawsuits.

Throughout the 1980s, deindustrialization began to affect the northeastern and midwestern cities that had been central to glass production. Financial struggles spurred new waves of automation, layoffs, and the beginnings of outsourcing within the glass industry. These changes stuck around. Today, according to World’s Top Exports, China leads glass production globally, exporting 25% of the world’s glass and glassware compared to 6.5% from the U.S.

The impact of deindustrialization on glass manufacturing communities ranged from minimal to devastating. In 1976, PPG closed its million-square-foot industrial complex in Mount Vernon, Ohio after 75 years of operating there. The city’s population continued to grow, but the poverty rate has crept up from 14.5 in 1960 (at the time, more than 7.5% less than the national average) to 15.6% in 2000 (4% greater than the national average). For decades, the factory passed through the hands of various owners (mostly serving as warehouse space) and sat in a state of progressive decay. Locals said it became a gathering place for drug users. This reflected an unfortunate trend for Ohio overall–according to FBI data, crime increased almost 250% in the state overall from 1960 to 1981, when it peaked.

Toledo’s fate was particularly bleak.

“When the glass industry began to decline, Toledo began to have an identity crisis,” says Barbara Floyd, retired director of special collections at the University of Toledo and author of the book The Glass City: Toledo and The Industry That Built It. “The glass industry tried to renovate and rejuvenate the downtown, spent millions and millions of dollars.”

The funding did not pay off. As both glass and car manufacturing continued to collapse, office and industrial spaces went vacant across the city. The 2008 economic crisis cemented the glass industry’s decline. By 2010, national glass manufacturing employment had shrunk to just above 80,000, about 50% less than a decade prior. Despite recent revitalization, Toledo maintains a reputation today as a post-urban wasteland of abandoned office buildings and high crime. Though the city’s crime rate has lowered since the 1990s, it is still, at about 457 violent crimes per 100,000 residents, significantly higher than the national average.

Corning fared better than Mount Vernon or Toledo. In 2011, high-end manufacturer Steuben shuttered its doors, leaving the area with no remaining glass factories. Corning Inc. had already closed its plant in nearby Fall Brook in 2001. The latter company, however, maintained its headquarters and research facility in the New York town, protecting a plethora of well-paying jobs.

A new lens on an old material

As glass faltered industrially, another sector found a new purpose for the material. The studio glass movement emerged in 1962, when ceramicist and UW-Madison professor Harvey Littleton began working with glass in Toledo. Littleton experimented with hot glass in his kiln after seeing small-scale glass studios in Italy. Without a specialized furnace, though, molding glass as precisely as clay was impossible. Littleton partnered with Dominick Labino, an engineer as well as Vice President and Director of Research at Johns Manville Fiber Glass, also in Toledo. Labino designed a furnace for Littleton, the first to make glass molding possible in the U.S. outside of a factory. Labino became a glass craftsman himself, joining Littleton and a whole generation of artists as the United States’ first studio glassblowers.

Littleton was acquainted with the glass industry from a young age; his father, Jesse Littleton, was Corning Inc.’s first physicist. Around 1915, Jesse and his wife, Harvey’s mother, pioneered the invention of Pyrex bakeware, the first glass used in cooking. In 1940, Jesse Littleton became Corning’s director of research. Harvey’s use of glass as an abstract, artistic medium was a sharp departure from his father’s focus on functionality and uniformity, but he was in some ways still involved in the family business.

Jesse Littleton once told his son, according to German artist Erwin Eisch in an article on American studio glass by Paul Hollister, “I have worked all my life to get bubbles and imperfections out of glass, and now you come along and bring all these flaws back into the glass.”

Harvey insisted later in his own career that “technique is cheap.” In other words, even the greatest scientific advancements could not replace artistic innovation.

Barbara Floyd believes that a divide emerged between industrial and studio glass once artists were able to shape glass individually,

“Now we have the technology that allowed for a single individual with a small blast furnace to do a lot of production in really, tremendously beautiful ways,” she says.

The studio glass movement was part of a larger crafts boom. As industrial manufacturing lagged in the 1970s, artisanal woodworkers, metalworkers and ceramists prospered. According to the American Craft Enterprises, a now-defunct organization that once hosted craft fairs across the country, craft sales totaled between $5 and 6 million in 1978 alone –$23 to 27 million in today’s dollars. The arts and crafts market has grown since, generating $40.5 million in 2020.

Charlie Manion, a friend of mine and manager of Firebird Community Arts in Chicago, once hand-produced scientific glassware in mass for a large company. He points out that studio glassblowers are using a process that manufacturers now consider out-of-date. Working with glass manually allows artists to prioritize creativity and aesthetics over profit and practicality.

“This is happening everywhere. Welders, printmakers, carpenters–the skilled trades are flooded with academy-trained artists looking for a way to earn a living wage,” Manion says. “It’s the pressure of industrial production, of just capitalist production, to take the most efficient path to whatever goal we’re trying to achieve. So artistic production, I think, is a way of reconsidering that relationship.”

Manion emphasizes the class difference between the populations benefiting from studio versus industrial glass. “Being able to make glass art is a luxury that most people can’t afford. It’s outrageously expensive to do, and there’s a limited market,” he says. “So most people that blow glass are wealthy hobbyists, and most people that produce glass industrially are workers.”

From industry to art

What’s left of domestic glass manufacturing in the U.S. remains concentrated in the Rust Belt–eight of the industry’s top 10 employers are in Pennsylvania, New York, and the Midwest. But studio glassblowing is adding relevance to a material long forgotten by many communities shaped by it. Today, the Rust Belt is home to three of the United States’ top five hubs for glass studios.

Pittsburgh’s deindustrialization a generation ago marked the transition from glass from an industrial material to a medium for studio art. In 2001, local glass artists Kathleen Mulcahy and the late Ron Desmett Pittsburgh Glass Center in an effort to foster a sense of community and promote economic revitalization. The non-profit now draws artists from all over the world and has hosted top glassblowers in residencies.

Other deindustrialized communities also benefited from the rise of studio glass. In 1980, the near-30-year-old Corning Museum of Glass reopened to include several new galleries. It also erected a research library dedicated to studio as well as industrial glass. In 1996, the Museum opened a space for studio glass classes. It expanded once again in 2001, adding a Hot Glass demonstration stage and one of the nation’s largest museum gift shops. Today, Corning is home to the world’s largest collection of glass and attracts 460,000 annual visitors from all over the globe.

The reign of studio over industrial glass is perhaps most visually acute in Toledo. Just two and a half miles from Libbey’s tired-looking glass plant and the run-down houses surrounding it lies the Toledo Museum of Art’s Glass Pavilion. The building is slick and transparent, rising low above the ground like a Frank Lloyd Wright design. The space, open since 2006, is composed mostly of glass from China.

Barbara Floyd wishes Toledo’s glass artists would give more credit to the influence of industrial glass on their work.

“[The glass pavilion] had absolutely no focus on it when it first opened. And it made me so angry, because it’s like, here’s this collection, the glass pavilion, and you could walk into that, and you would have absolutely no idea why it was in Toledo,” she says. “There wouldn’t be a glass artistic collection in Toledo without the glass industry, because of Libbey,” she says.

Industrial glassmaking in the United States has made a modest recovery since the 2008 recession, but it remains a shell of its former self. Like other industries, glass manufacturers have concentrated in places with looser regulations and lower wages. Today, the most lucrative glassmaking ventures in the United States focus on specialty products like biomedical and advanced automotive technologies. Corning Inc. now manufactures fiber optics, scientific glassware and screens for electronic devices, among similar products. 52% of the company’s revenue, however, comes from Asia and the Pacific, compared to 36% from North America.

Between 1996 and 2004, Owens-Illinois bought up 50 plants outside the United States. At the same time, it drastically reduced its domestic employment. From its heyday up to 2022, the O-I bottle plant in Streator scaled down from 16 to 4 furnaces. The trend continues–O-I recently announced that it plans to shut down yet another furnace in Streator. The company is currently negotiating mass layoffs with the United Steelworkers’ Glass, Molders, Pottery, Plastics and Allied Workers Council.

Foreign competition and climate change make a resurgence of domestic glass production unlikely. Glass itself is more environmentally friendly than plastic, as it is 100% recyclable. Cullet makes up 40% of each batch in Owens-Illinois furnaces. But the U.S. recycles only 25% of flat glass, compared to 74% in Europe. Coupled with the high fossil fuel emissions from the actual manufacturing process, transitioning to greener glass production would cost U.S. companies too much to justify increasing domestic output.

The state of studio glass is not much more secure than glass manufacturing, but it is better by comparison. COVID-19 sent the cost of glassblowing skyrocketing across the world. American artists struggled, but the U.S. actually became a sort of refuge for creators in other parts of the world where studios shut down, including Italy.

Mount Vernon, Ohio’s economy still centers on manufacturing–today, its top employer is Ariel Corporation, which produces natural gas compressors rather than plate glass. The river of glass–repurposed from the old PPG buildings–glimmering in Ariel Foundation Park is in many ways a reminder of the inescapable fragility of industry. But it is also a beautiful work of art. The studios enduring across Ohio, Pennsylvania and Upstate New York follow the same mentality–when a material loses its industrial advantages, make it beautiful instead.

Dora Segall is a freelance writer and photojournalist based in Chicago. They primarily report on music but also cover other artistic mediums, labor, gender and sexuality. Dora’s work has been published in outlets such as Belt, SPIN and The Chicago Reader.